Specialized Laboratory in Equipment Failure Analysis Services: Your Trusted Partner in Failure Analysis for Brazil and South America

Precise Diagnostics in Equipment Failure Analysis for Fatigue and Breakage Prevention

With over 25 years of troubleshooting expertise and a long-standing history of successful investigations across diverse sectors in Brazil and South America, Testmat is your trusted laboratory for comprehensive failure analysis. We cater to a diverse range of industries, from Oil & Gas to the Food Industry, using state-of-the-art methodologies.

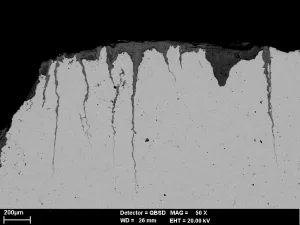

Fractography and Scanning Electron Microscopy: Uncovering the Root Causes of Mechanical Failures

“Understanding the cause of your equipment’s failure is the first step toward improvement.”

Comprehensive Services in Equipment and Component Failure Analysis

Microscopic Understanding of Mechanical Failures through Scanning Electron Microscopy

Our comprehensive failure analysis—covering gears, connecting rods, bearings, shafts, crankshafts, and more—helps you identify manufacturing defects and the root causes of mechanical failures in industrial machinery and structures.

Custom Remediation Strategies for Optimized Performance

Testmat’s services extend beyond merely identifying problems. We provide tailored solutions that include:

- Interpretation of failure data, including on-site review

- Detailed examination of parts to ascertain failure mechanisms

- Root cause analysis covering design, fabrication, transportation, installation, and service

- Non-destructive evaluation strategies for remaining intact components

- Advice for remedial actions to prevent further failures, including design and fabrication reviews for replacement components

Elevate Your Product Reliability and Performance with Testmat

Our failure analysis not only identifies the reasons for equipment failure but also significantly improves your operational reliability and product performance in the field. Learn more about our approach here.

Upgrade Your Operational Processes with Our Cutting-Edge Failure Analysis Lab

Discover how our state-of-the-art laboratory can help you significantly enhance your Maintenance, Engineering, and Quality processes.

Advanced Techniques and Solutions

Testmat employs a variety of innovative techniques for comprehensive failure analysis, including:

- Expert multidisciplinary data interpretation

- Characterization of failure modes through advanced microscopy techniques

- Stress analysis and numerical modeling, including dynamic simulations

- Development of non-standard test methods for novel applications

Team Training Services in Brazil

In addition to our failure analysis services, Testmat also offers specialized team training programs in Brazil. Equip your staff with the knowledge and skills they need to prevent failures and improve operational efficiency.

Ready to Uncover the Root Cause of Your Equipment Failures and Boost Operational Efficiency?

Don’t let equipment failure setbacks keep you from achieving maximum productivity and reliability.

Secure your operational future today.

- Book a Free Consultation: Speak directly with one of our experienced engineers to understand how we can tailor our services to meet your needs.

- Request a Custom Quote: Get a tailored failure analysis plan and quote that fits your organization’s requirements.

- Sign Up for Our Specialized Team Training: Empower your team with the knowledge and skills they need to prevent failures and increase operational efficiency.

Take the First Step to Unbeatable Efficiency and Reliability: Click here to Connect With Us!

Key Takeaways:

- Expertise across diverse industrial sectors

- Comprehensive failure analysis services from microscopic to macroscopic levels

- A multidisciplinary approach for accurate root cause identification

- Tailored remedial strategies

- Team training services programs